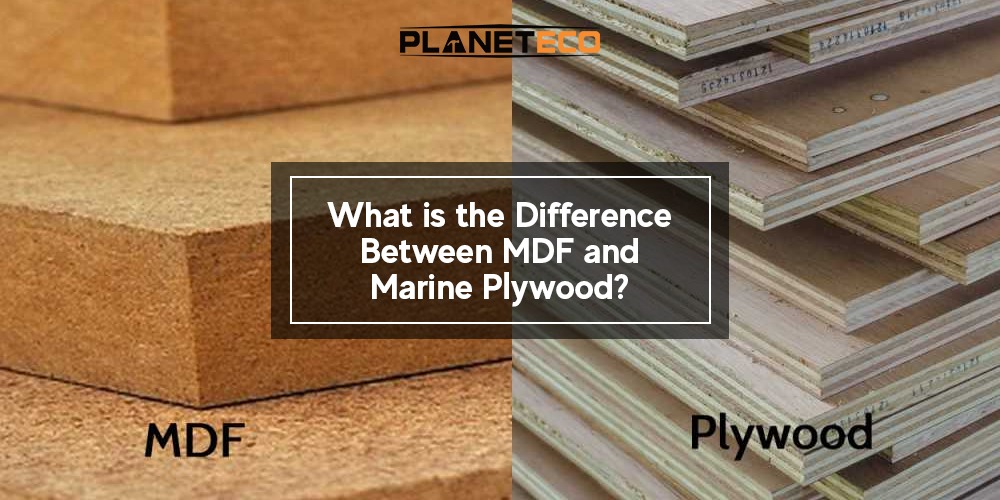

Choosing the right material when constructing a structure or doing a woodworking project is crucial to getting the best outcome. MDF and marine plywood are two relatively popular materials, each with its characteristic features and usages.

This is the second blog in the series where I am comparing two such types of wood to build a proper understanding, and for whom the question is PLYWOOD or MDF, it’s all here.

Knowing these differences will benefit any client consulting a professional contractor or anyone who wishes to attempt do-it-yourself projects, enabling them to achieve both a functional and beautiful outcome on their remodels or new builds.

Understanding MDF

What is MDF?

Medium-density fiberboard (MDF) is an economical construction or finishing material consisting of a panel made with hardwood and softwood leftovers that are processed into fibers and combined with wax and resin binder.

These components are then formed into panels by means of heat and pressure. MDF is a favorite for interior work since its surface is smooth, does not check like plywood, and is very uniform in thickness.

Key Characteristics of MDF

i. Smooth Surface

MDF’s compact wood particle structure gives it a smooth and uniform surface that is suitable for finishing with paint or veneer.

ii. Consistency

It also uniformizes the density throughout the board since there are no knots or voids on the wooden board, making it easier to cut it into the desired shape and size.

iii. Workability

Most woodworkers can relate to the fact that MDF is quite easy to work with by simply using regular carpentry tools. It can also be drilled, cut, and shaped without damaging the material’s surface in any way, such as by chipping.

iv. Cost-Effective

It is usually affordable compared to solid wood or plywood, making it suitable for large-scale projects.

Common Uses of MDF

- Furniture: Applies in the production of fixtures like flat-pack furniture, shelves, and cabinets, among other applications.

- Interior Paneling: Containing less than 0. 1% silica and other undesirable impurities, this material is perfect for use in wall cladding and ornamental purposes on account of its polished surface.

- Doors: It is applied on interior doors and door frames.

- Moldings: Ideal for tiny edges, ceilings, doors, and windows, and any other intersection that requires a neat trim.

Understanding Marine Plywood

What is Marine Plywood?

Marine plywood is a high-quality type of plywood used to resist moisture and difficult marine conditions. CNC ply is manufactured from high-density, high-quality face, and core veneers, which have few or no defects and are bonded together with water-resistant adhesive.

Marine plywood is generally classified as hardwood. This type of plywood is characterized by strength and sturdiness, as well as resistance to delamination and fungal growth.

Key Characteristics of Marine Plywood

i. Water Resistance

It is specifically designed to prevent contact with water, making it suitable for areas with high humidity.

ii. Durability

Although its name suggests that it is designed for use in marine environments, marine plywood is incredibly strong and made from hardwood species and high-quality adhesives.

iii. Void-Free Construction

Laminated Veneer Lumber Canadian insulation is also attributed to the veneers’ lack of gaps or voids.

iv. Phenolic Resin Adhesive

Phenolic resin exhibits great adhesive properties, and it is very effective in waterproofing.

Common Uses of Marine Plywood

- Boat Building: A special type of fabric used in the construction of hulls, decks, and other applications for the marine sector.

- Outdoor Furniture: It is perfect for tables, chairs, and other structures in a garden or a compound with an open space.

- Exterior Construction: It can be used for roofing, siding, and other exterior applications.

- Bathroom and Kitchen Cabinetry: This material is ideal for use in furniture, particularly those places that are exposed to a lot of humidity.

Comparing MDF and Marine Plywood

MDF and Marine Plywood have been discussed and compared to help us understand them better and identify the best areas of application for each product.

Moisture Resistance

- MDF: It is not water-resistant. Whether fully or partially, MDF will always absorb moisture, leading to swelling and deterioration. It should preferably be used in dry and indoor places, though it is also effective when used in highly humid places.

- Marine Plywood: It is highly water-resistant. It is particularly suitable for use where moisture exposure is likely to be high, both indoors and outdoors.

Strength and Durability

- MDF: It is sturdy, for instance, during construction or any other function for which it was intended, but less hard or as durable than marine ply when used in wet environments. It is easily injured by impact and can droop when under considerable weight.

- Marine Plywood: It is very tough and resistant, or resilient, as it may be best to call it because it contains the best of both and then some. It is resistant to wear and tear while consistently supporting and bearing considerable weight without showing any signs of wear or damage. For this reason, it is suitable for structural purposes.

Workability

- MDF: It is cheap, easily malleable, and easy to cut, shape, and drill compared to other materials. Being relatively flat also makes it easier to paint or veneer.

- Marine Plywood: Takes longer to chop and scribe because of its solid nature compared to Cedar and Redwood. Nonetheless, the former offers very high structural utility once it has been placed in a structure.

Cost

- MDF: It is typically cheaper than marine plywood and is recommended for indoor use only.

- Marine Plywood: It is cheaper since it serves the same purpose, is of higher quality, is more durable, and is water-resistant. This implies that the charger that costs more is more appropriate for use in some tough conditions.

Environmental Impact

- MDF: Usually processed from the wood fibers mixed with the resin, which is often formaldehyde. Some forms of MDF are environmentally friendly and produce reduced emissioemissionsmaldehyde resins.

- Marine Plywood: Though sometimes manufactured from sustainably harvested wood and formaldehyde-free adhesives, it might have its drawbacks, being at times considered (un)eco-friendly if produced from raw materials harvested unsustainably.

Choosing the Right Material for Your Project

To compare and contrast MDF and marine plywood, we should first think of the features your particular application will demand. Here are some factors to keep in mind:

Indoor vs. Outdoor Use

- Indoor Projects: It is commonly used in indoor projects for furniture, cabinetry, moldings, and anything that requires a smooth, opaque surface.

- Outdoor Projects: Marine plywood is suitable for outdoor use and destinations where it will be exposed to wet weather or water, such as boats, outside cladding and furniture, and landscaped furniture.

Moisture Exposure

- Low Moisture Areas: Some of the tips are: MDF was recommended for use in areas that are not exposed to damp, such as the living room, bedroom, and office, among others.

- High Moisture Areas: Special types of plywood, such as marine-grade plywood, are perfect for places with high humidity levels, such as bathrooms, kitchens, and open-air structures.

Structural Requirements

- Non-Structural Applications: This MDF is appropriate for uses where heavy-duty intent or strength qualities are unnecessary.

- Structural Applications: Marine plywood is essential in structural uses since this type of board requires strength and durability.

Budget Considerations

- Budget-Friendly: MDF is suitable for interior use and is cheaper than other types of wood, but it is costly in quality for projects that aim to be affordable.

- Long-Term Investment: Compared to marine plywood, it is a bit on the more expensive side, but it is recommended since, in the long run, it proves to be cost-effective and highly durable, especially for those who are to set their projects in wet or outdoor areas.

MDF vs. Marine Plywood – Making the Right Choice

The two most common types of wood substrates used in cabinetry and furniture making are MDF boards and Marine Plywood boards. MDF boards and Marine Plywood boards are two of the most popular kinds of wood substrate products that are commonly used in cabinetry and furniture making today.

It is essential to know the key factors that set MDF and marine plywood apart to determine which material will work best for your project. MDF is best suited for indoor use, where a planar or slightly textured surface is the best option. Thus, while standard plywood is the right choice when using the product in conditions where it is exposed to moisture and when high strength and durability are needed, marine plywood is the better choice for virtually any project.

If you are looking for MDF and marine plywood, Planeteco offers a wide range of Services to assist with your building needs. Whether you are a respected contractor or amateur, Planeteco ensures you get quality materials and guidance to make your endeavors worthwhile. Browsing through their online catalog, you will likely find the right supplies for your next construction project.

Therefore, you should make an informed decision based on your particular project to get the best results for your problem-solving needs. We guarantee that your work will last for a long time and provide you with the results that you need.

Choose the right material. We at Planeteco are always ready to assist you in creating the perfect products.